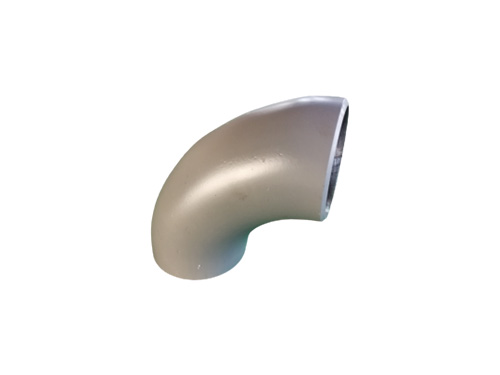

Carbon steel 90 degree elbow is easy to use. It can be divided into: low carbon steel, medium carbon steel, high carbon steel, 20 steel (20g), Q235 A, Q235B, etc. the 90 degree carbon steel elbow is characterized by relatively high carbon content.

1. Manufacturing process of carbon steel 90 degree elbow can be divided into pushing, pressing, forging, casting, etc.

2. According to the standard of manufacturing carbon steel 90 degree elbow, it can be divided into national standard, electric standard, ship standard, chemical standard, water standard, American standard elbow, German standard, Japanese standard, Russian standard, etc.

3. According to the curvature radius of 90 degree carbon steel elbow, it can be divided into long radius elbow and short radius elbow. Long radius elbow means that its radius of curvature is equal to 1.5 times of the outer diameter of the pipe, i.e. r = 1.5D; while that of short radius elbow is equal to the outer diameter of pipe, i.e. r = 1.0d.

Problems needing attention in machining of carbon steel 90 degree elbow

The principle to determine the heating temperature of carbon steel 90 degree elbow is that the austenitizing temperature of the material is above, and the main compressive stress on the inner wall of the elbow is less than the yield of the material at this temperature. The higher the material temperature, the higher the yield temperature.

According to the standard is divided into carbon steel 90 degree elbow, national standard, non-standard, standard: German standard, Japanese standard, American Standard, British standard elbow. The raw material of carbon steel seamless elbow is seamless steel pipe. The main production process is round billet → heating → piercing → three roll cross rolling, continuous rolling or extrusion → pipe stripping → sizing (or reducing diameter) → cooling → straightening → hydrostatic test (or flaw detection) → marking → warehousing. Schxx is wall thickness grade, 90E (s) is short radius 90 degree carbon steel elbow, 90E (L) is long radius 90 degree elbow; 45e (L) is long radius 45 degree elbow; 45e (s) is short radius 45 degree elbow; 180E (s) is short radius 90 degree carbon steel elbow; 180E (L) is long radius 180 degree elbow.